INVENTORY MANAGEMENT

The inventory optimization leverages purchase and sales data to find the optimal stock levels for different customers and product groups to reduce capital tied up in inventory where that is the answer and increase service levels where that is appropriate. Hands on, which stock levels are optimal to serve the customers with the right service levels.

The inventory planning and allocation process consulting improves the processes and structures for demand and supply planning to secure a long-term sustainable planning that provides the best ability to provide the best service levels to the customers at the lowest cost. Some specific elements are forecast accuracy analysis, supply chain planning tools and best practice supply chain planning processes.

SCOPE

Optimize inventory levels

Free up capital

Improve product availability

Improve inventory planning processes

Decide what inventory to store where

Simulate different inventory strategies

Objectives

Optimal inventory levels: an audit of current inventory levels based on current and potential planning factors

Improved inventory planning processes: optimal inventory planning processes for long-term efficiency to create the best planning factors

Improved forecasting: evaluation of forecasting accuracy and how to improve it

Inventory strategy: selective inventory and sourcing strategy. What to stock and where.

Deliverables

Methodology

Why Establish?

Experience

Establish has focused on supply chain management consulting for 48 years. Inventory management requires optimization and algorithms but is really delivering results when put in a context. Our supply chain consultants have the experience from all aspects that are impacting the optimal inventory strategy, from supply planning through transportation and demand planning.

The Right Tools

For inventory optimization Establish use the premier supply chain planning software, Optimity. This allows us to build a digital twin to simulate different strategies, calculate optimal inventory levels according the best algorithms and through AI find the best forecasting method and calculate the potential opportunities.

Data cleansing and profiling is critical to inventory management projects. Establish leverages proprietary software that is built bespoke for supply chain analysis. Our network optimization tool Assign is a great extension to find the right distribution locations and total supply chain cost optimizations.

Fact Based, Result Oriented Methodology

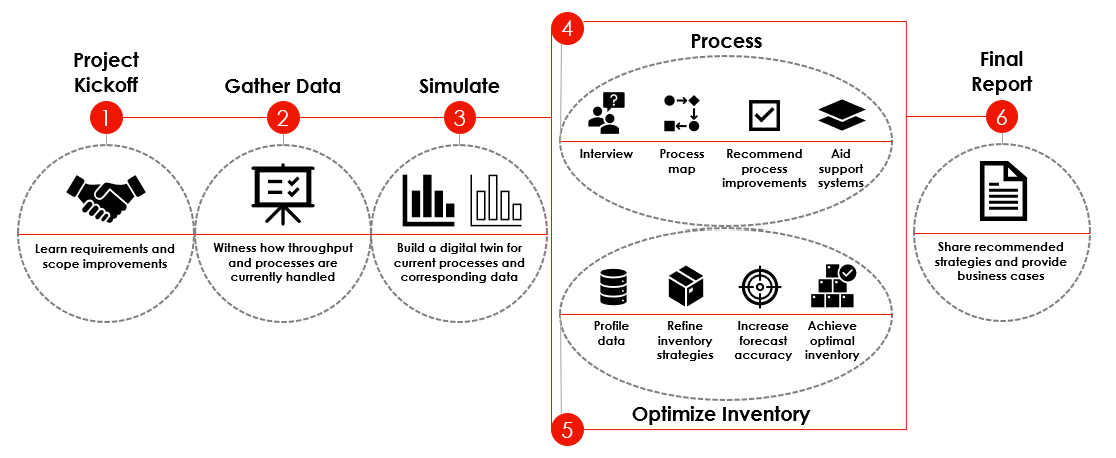

Establish inventory consultants follow a result oriented methodology that is supported by tools and software in every step. This maximizes the efficiency and secures the full leverage of our experience for your project.

TOOLS & METHODS

Within inventory optimization we are using state of the art tools and methods. Below you find some of the most important tools:

Relex — Supply Chain Planning

Assign — Network Optimization

Supply Chain Profiler — Data Cleansing and Profiling

CASE STUDIES

Establish has a long track-record within inventory management. The case studies below are just a few examples of achievements from Establish's supply chain consultants together with clients within inventory management.

Inventory Optimization at a Global Electronics Company

Establish worked with a large electronics company to review its inventory strategy. With a global customer base and operations in the US, Europe, and China, the $350M manufacturer was struggling to meet growing customer expectations.

Inventory Management for a Device Manufacturer

Establish help a device manufacturer reduce inventory carrying costs while improving their customer service levels.